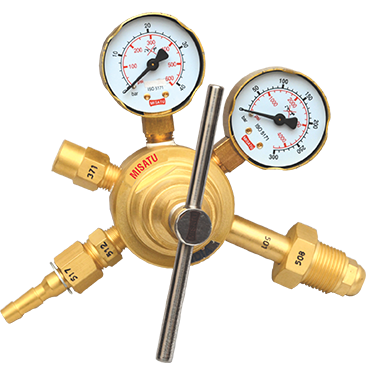

M Series High Pressure Single Stage

Home / M Series High Pressure Single Stage

M Series High Pressure Single Stage

These general purpose single stage regulators are recommended for inert and non-corrosive gas applications where precise control of delivery pressure is not necessary. They are well suited, where constant delivery pressure regardless of fluctuations in cylinder pressure are required.

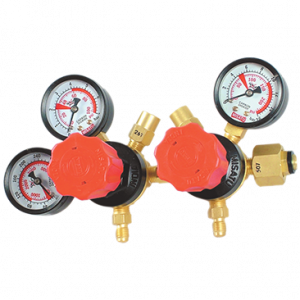

Optional Needle Valve

Technical Data Sheet

| Gas Service | Model | Model For Flow Meter | Cylinder* | Delivery | Connections* | |||

|---|---|---|---|---|---|---|---|---|

| Pressure Bar | Guage Range Bar | Pressure Bar | Guage Range Bar | INLET | OUTLET | |||

| *As per customer requirement | ||||||||

| INLET - IS 3224 : 2002 | ||||||||

| OUTLET - ISO/TR 70470 : 1988 | ||||||||

| 1bar = 14.504 psi = 1.0197 kgf/cm2 | ||||||||

| 1 psi = 0.06894 bar = 0.07031 kgf/cm2 | ||||||||

| 1 kgf/cm2 = 14.223 psi = 0.98068 bar | ||||||||

- Designed for easy maintenance.

- No metal to metal seat in nozzle for easy opening & closing.

- All component machined on CNC machine.

- All components are ultrasonically cleaned, also polishing & deburring in finishing machine.

- Weated area spring & poppet (pin) made from stainless steel to avoid rusting.

- Pressure key made from stainless steel & roll threaded to avoid worn out bonnet thread.

- Gas filtration with stainless steel wiremesh twice from inlet to restrict dust particle to enter.

Body – Forged Brass

Bonnet – Forged Brass

Diaphragm – Reinforced Neoprene

Nozzle – Brass

Seat – PTFE

Filter – Stainless Steel Wire Mesh

Seat Return Spring – Stainless Steel

Bonnet Spring – Spring Steel Plated

Adjusting Knob – Stainless Steel Screw

Optional Needle Valve

Body – Forged Brass

Stem – Stainless Steel

Packing – Teflon

- Cutting

- Heating

- Research Lab.

- Refrigeration

- Process Control

- High pressure Testing

Maximum Inlet – 4000 PSIG

Outlet Ranges – 0-15 BAR, 0-20 BAR, 0-25 BAR

Body Port – 1/4 NPT F