Tig Water Circulator

Home / Tig Water Circulator

High-Powered Stainless Steel Pump with our more than ten years welding experience. The water cooler enjoy superior quality and capability.

Features

- Stainless Steel (long life for torch) Pump corrosion free.

- No priming required. Quick fill in & drain out.

- Simple Maintenance.

- 200 wmm Fan for the big radiator. No water leakage guarantee.

SPECIFICATIONS

| Input | 230V 50/60Hz |

| Motor | 260W(0.9A/220V) |

| Cooling Capacity | 1.5kw(1l/Min) |

| Duty Cycle | 100% |

| Max Pressuer | 3bar |

| Tank Capacity | 9 Liter |

| Flow Rate | 8.5/Min. At 6mh |

| Operation Temperature | -20 C~60 C |

| Dimension | 24” (L) X 15” (W) x 12” (H) |

| Net Weight | 22.0 Kg |

PRECAUTIONS

1. For long time not using the coller, Re-start the motor and make sure the water is pumped out to prevent water cooling torch damaged.

2. Make sure the tank is filled with enough clean water and all the connectors is fixex firmly. Always sure the water tank is kept enough water over the safety line. Pump may be damaged while the tank is without water.

3. Make sure the input voltage is correct. See the technical data Or motor may be burrn out!

4. If the motor works well (there is windy from the radiator) but the water draining is small or no water, please pump in pressure air from compressor to inter or outlet for 20 seconds.

5. When the motor cant work:

- The input voltage is too low, please change the electric supply.

- When the starting capacitor is bun out, please change a new one.

- The pump cant work if the motor stop long time. Please pump air into the INPUT or OUTPUT for 20 sec. Make the pump work again.

- The motor has to be replaced if it is burn out.

6. When this equipment incline too much, the water in tank may overflow, the motor pump becomes a short lifetime.

7. This equipment is used for cooling the torch of welder, so that the torch doesent bum-up for the over high temperature. The cooling fluid must be pure water or distilled water to avoid the torch or coprum walls up and burn-up the torch. Please and water upper warm line, when the water under the warn line 3CM. If the water in tank has been used for a long time and very dirty, please open the cover under the bottom of the tank and change the new water.

8. Because there is a motor in the equipment, the water cooler cant be used in the rain. No water is allowed to come in the loop of the motor avoiding a shortage to bun-up the motor.

MAINTENANCE

1. Keep the interior dry and clean.

2. Adding or changing the water in time.

3. Open the trunk every half a year, clean the interior with the air gun of the compressor.

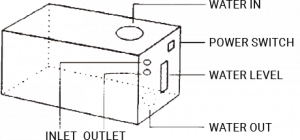

INTRODUCTION OF PANEL

1. Confirm the input voltage (230v see the nameplarc that on the machine)

2. Insert the OUTLET of the water cooler into the INLET of the welding machine.

3. Insert the INLET of the water cooler into the OUTLET of the welding machine.